Tarmac Driveway Cost

- The average cost of a tarmac driveway is around £2,200.

- It will take approximately 4 days to complete this type of job.

- NEW! Our tarmac driveway cost calculator, which gives you a quick and no-hassle way to get an idea of what this type of job will cost you.

- A breakdown of how much it typically costs to tarmac a driveway and what impacts the costs you'll be quoted in 2025.

- Expert advice from tradespeople on MyJobQuote about tarmac driveway installations.

- How to find and hire a tarmac driveway specialist near you.

Looking into how much a new tarmac driveway costs in 2025?

Tarmac driveways are a great way to add kerb appeal to your home and also create a practical place to park your car.

The average cost to tarmac a drive in the UK is between £700 and £6,000. But the exact cost you'll pay to get a tarmac drive depends on the size of your driveway.

In this guide, we cover everything you need to know — including tarmac prices per m², cost of tarmac drives per m², coloured tarmac driveway costs, and much more! This will make it easier for you to more accurately estimate the cost of a tarmac driveway.

Ready to get a quote for a new driveway?

Get free, no obligation quotes from local tarmac driveway installers who can handle all of this for you. MyJobQuote is fast, easy, and connects you with professionals in your area.

Want to find out more before you start getting quotes?

Continue reading below!

£2,200

Table of Contents

- How Much Does it Cost to Tarmac a Drive?

- How Much do Tarmacers Charge?

- How Much Do Tarmac Supplies Cost?

- Additional Tarmac Driveway Costs

- Factors That Impact Tarmac Driveway Costs

- What's Involved in Tarmacing a Driveway?

- How Long Should You Leave a Driveway After Tarmacing?

- Can I Tarmac a Driveway Myself?

- Benefits of Tarmacing a Driveway

- Tarmac Driveway Repair Costs

- Cost of Resurfacing a Driveway

- Cold Lay Tarmac vs Hot Mix Tarmac

- Concrete vs Tarmac Driveways

- Cleaning and Maintaining a Tarmac Driveway

- Tarmac Driveway Alternatives

- Cost of Removing a Tarmac Driveway

- Checklist: Hiring a Tarmac Driveway Installer

- FAQs

- Sources

Tarmac Driveway Cost Calculator

How Much Does it Cost to Tarmac a Drive?

Let's start by taking a look at average tarmac costs per m²...

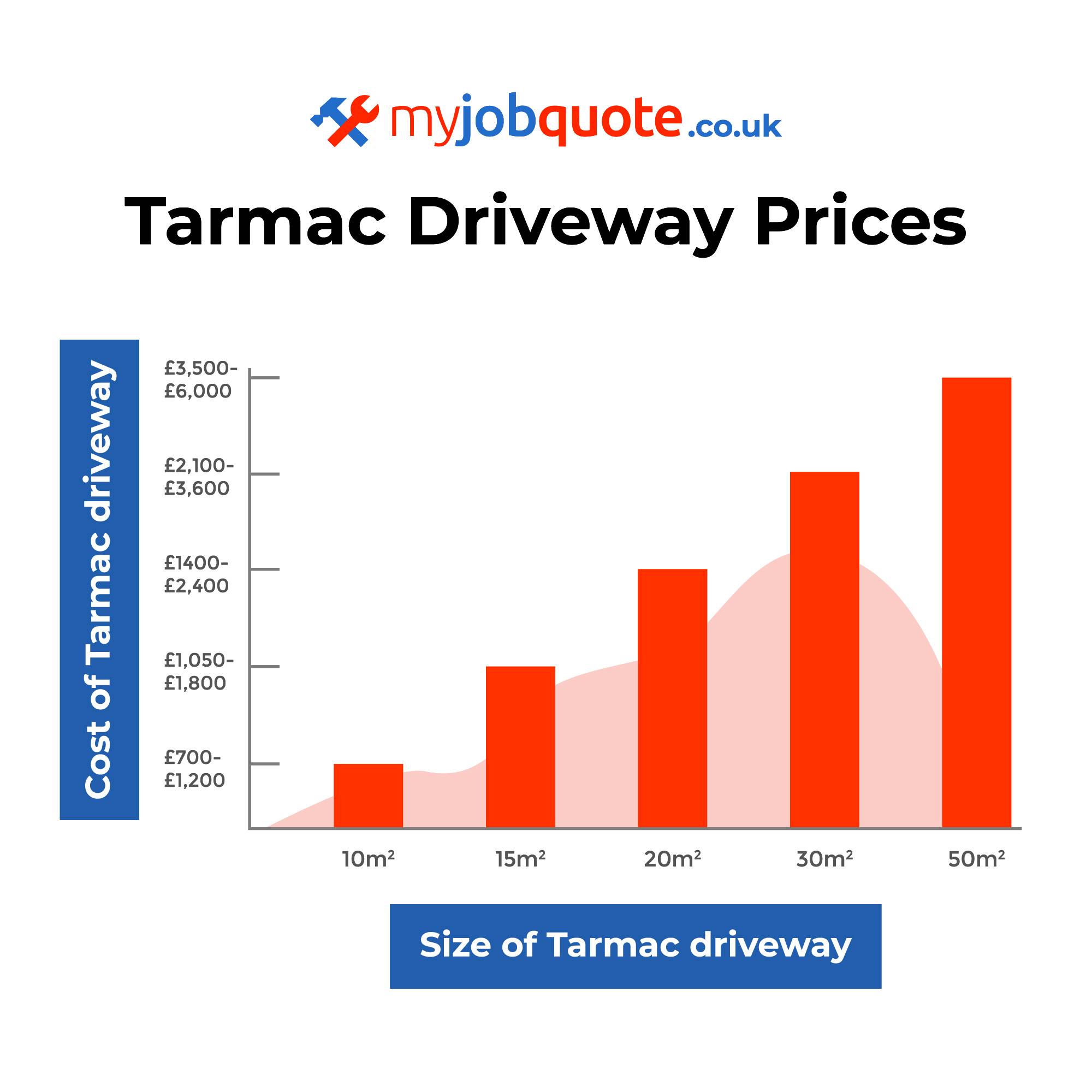

In short, you can expect to pay between £70 and £120 per m² for the cost of tarmacing a drive.

This is what that translates into for different sizes of tarmac driveways:

| Number of Cars | Driveway Cost |

|---|---|

| 1 Car Tarmac Driveway | £700 - £1,200 |

| 2 Car Tarmac Driveway | £1,400 - £2,400 |

| 3 Car Tarmac Driveway | £2,100 - £3,600 |

| 4 Car Tarmac Driveway | £2,600 - £4,800 |

What Can Impact Tarmac Driveway Costs?

There are a few key things that will impact the price you'll pay for tarmac driveway installations:

- Tarmac driveway prices drop in cost per m² for larger driveways

- Weather conditions when a tarmac drive is being installed

- Accessibility of the driveway (i.e. is the driveway accessible to larger vehicles?)

- Preparation work needed before the project starts (e.g. removal of obstructions, creating driveway access points, or dealing with drainage concerns)

- Aesthetic choices, such as the tarmac colour and any decorations

For instance, if a tarmac drive installer works during heavy rain, this can cool down the tarmac prematurely and may not offer the best results. Tarmac is a sturdy substance, but it's preferable not to complete the work in torrential rain!

How much would a 2 car driveway cost in tarmac with a border of block paving, drainage, and 2 new manhole covers?

Tarmac Prices

Tarmac Price Per M²

The average tarmac price per m² is between £70 and £120. However, the tarmac cost per m² will vary depending on what you're after and where you're located in the UK.

While you'll pay more for labour and time when tarmacing a larger drive, the cost per m² that you'll pay for tarmac will decrease.

On the other hand, you'll pay a higher price per m² when tarmacing a smaller drive - but it'll take less time which means you won't pay as much for a labourer's time.

Check out the price of a tarmac drive based on m² below:

| Size of Driveway | Driveway Cost |

|---|---|

| 10m² | £700 - £1,200 |

| 15m² | £1,050 - £1,800 |

| 20m² | £1,400 - £2,400 |

| 30m² | £2,100 - £3,600 |

| 50m² | £3,500 - £6,000 |

The above table is a guideline only as there can be a multitude of other factors to consider with the tarmac drive cost, such as being an irregular shape and needing to remove existing materials, which can add to the duration and cost.

Additionally, the price can be lower if you're overlaying an existing tarmac drive.

Tarmac Price Per Ton

Hot-mix tarmac cost per tonne equals to £45 on average, and this provides 8m² coverage.

The price of tarmac per ton remains the same, but the less you buy isn’t cost-effective as you'll likely have to pay £100 and £150 for delivery costs, have a place to store the hot mix tarmac and be ready to lay it almost immediately.

Cold lay tarmac is also available, however this is generally used for repairs as it's not suitable for tarmacing a whole driveway due to it not being as durable - plus curing is limited.

I'm looking for ballpark figures for a driveway extension (single into a double). The area to be converted is currently covered in loose gravel (about 120mm deep) with soft earth underneath. The area is also sloped towards the house at about a 10 degree gradient. It's around 11m² in total.

How Much do Tarmacers Charge?

Let's now take a look at how much tarmac driveway specialists charge, how many tradespeople are required on-site for this type of job, and how long laying a new tarmac driveway tends to take.

Labour Costs

Our data indicates that driveway professionals usually charge within the region of £150 to £200 per day and rarely give a fixed price when quoting the cost of a tarmac driveway.

How Long Will Tarmacing a Drive Take?

It can take a minimum of 1-2 days to tarmac a small driveway, depending on the size of area, condition and providing adverse weather doesn't cause any delays. However, larger driveways or those requiring additional preparation may take 5 to 7 days (including excavation work, installing drainage systems and laying a base to work with). In some instances, such as more complex designs or if a job has been impacted by the weather, the project instead could take 1 or 2 weeks to complete.

However...

You'll need to ensure that your driveway is consistently accessible to prevent delays and (hope!) that the weather conditions remain the same throughout.

How can I ensure a driveway contractor is totally legitimate and will do a good job?

How Many Tradespeople Will You Need To Hire?

In theory, it is possible for one person to complete a small tarmac driveway of 10m², however specialists tend to work in pairs to tarmac the drive as efficiently as possible. Because of this, you should expect to pay within £300 and £400 per day in labour costs alone.

A single driveway within the region of 10 and 20m² can take two people between 1 to 2 days to complete, and for a more substantial area up to 80m², around 4 and 5 days.

This is on the assumption that the existing drive is in an acceptable state, that the weather conditions are relatively dry and that no other additional work is completed - such as a dropped kerb or landscaping.

These are just some of the criteria that can add to the cost of tarmac driveway prices.

How Much Do Tarmac Supplies Cost?

Most supplies can be bought-in yourself from DIY stockists. In particular, cold lay tarmac is readily available.

A standard 25kg bag will usually cover approximately between 0.2m² and 0.3m² with around 40mm of depth, although this can vary depending on the aggregate and how compacted it is once laid.

But what about cost per metre square?

When calculating per m², it comes to between £40 and £60 per m². With that in mind, this option is best suited for repair work rather than a new driveway.

However, some trade prices drop to as little as £8 per bag if bought in larger quantities - meaning the cost can be as low as £32 per m².

Again, tarmac driveway material costs will lower with the size of the driveway.

| Type of Tarmac | Cost |

|---|---|

| Cold lay tarmac | £8 - £15 per 25kg |

| Hot-mix tarmac | £45 - £60 per tonne |

But what's the cheaper tarmac option here?

Hot-mix tarmac is much cheaper compared to cold lay tarmac on a larger scale (enough for a driveway, for example). That's why cold lay tarmac is mostly used for repair work only.

However, hot-mix tarmac is sold by the tonne and needs to be delivered.

What is the price of tarmac per ton for supply only?

The cost of this can vary based on location, how much you require, and the company you choose.

For a 30m² drive, you will need around 3 to 4 tonnes costing between £285 and £440 including the delivery cost of £150 to £200. You would also need to consider where to store the materials in the meantime.

What would be the most cost effective option for a new driveway? Needs to be firm, low maintenance, and will have 4 cars on.

Additional Tarmac Driveway Costs

What else can you expect to pay for when tarmacing a driveway?

Here is a table full of extra costs you might have to pay when budgeting the cost of a new tarmac driveway:

| Additional Work | Cost |

|---|---|

| Landscape gardening | £20 - £30 per hour (depending on the work involved) |

| New front door (UPVC) | £550 - £600 |

| Painting of the house exterior | £800 - £1,200 |

| Single car port | £2,500 - £3,000 |

| Security lighting (x1 outside) | £100 - £150 |

| Driveway gate (metal) | £250 - £300 |

| Skip hire (4 – 5 yard) | £110 - £240 |

| Roof cleaning | £300 - £500 |

| Dropping the kerb | £600 - £1,000 |

| Window cleaning | £10 - £30 |

Factors That Impact Tarmac Driveway Costs

There is a multitude of circumstances that can increase or decrease the cost of tarmarcing a driveway, from the usual aspects of sizes, accessibility, and tailored options to the appearance of the tarmac and new drainage systems.

The Size of the Driveway

As touched upon earlier, with larger work areas come more labour costs and the time involved in doing the work. While a larger area will cost more in the long run, the material costs will decrease.

Poor Access

Driveways that could potentially cross over onto a public footpath or grass verge may pose a problem, not just with planning permission, but also access to the job in question.

For example, if a public footpath crosses the driveway, it may be difficult for the contractors to work on it without getting permission to continue.

This can be remedied by contacting the Highways Agency and/or your local authority. In some cases, the driveway may be shared with a third party so you will need to gain consent from them before continuing with work.

Odd Shaped Driveways

Oddly shaped driveways won’t necessarily be affected by the tarmac process as it’s laid as a liquid, meaning it will form into the shape it’s poured onto. There are two areas to be aware of, however.

The first is to ensure that there is a slight slope so water can run off the driveway into adequate drainage facilities away from the home.

The second key area is that you will need to apply edging to the driveway. Initially, this is to ensure that the tarmac does not move or crack, but it adds an aesthetic quality to it as well.

Coloured Tarmac Cost

Changing the colour of the tarmac means adding a dye to the mix.

Red is the most common type of tarmac colour that you'll see when you're out and about. But if that's not for you, then there are other options - such as green, grey, blue, plus many more.

The cost of red tarmac increases the average price by around £10 to £20 per m²; the higher end of this estimate tends to be for a smaller area.

An average quote, bearing in mind the size of the driveway and location, comes to as much as £65 per m² for a 30m² driveway.

What different colours of tarmac driveway are available (aside from black)?

New Driveway Draining System Cost

Unless you have access to an existing soakaway, you could be looking at a starting price of £500 to £1,500 for a new soakaway or new channel - with the duration of this work taking about 1 day.

Infrequent Slopes

The problem with infrequent slopes affects water flow and drainage and will pose a problem if not correct. As part of the planning permission with driveways, all water must be directed away from the house but not cross a public space.

New channels and soakaways can be created, but if the water doesn’t flow, it won’t make a difference, and there will be areas where the water will reside, gradually wearing away into the tarmac surface.

What's Involved in Tarmacing a Driveway?

Tarmac is a hardy substance and doesn’t need as much preparation as alternative driveway materials. It can also be arranged on other elements (excluding lawns).

The following steps will assume that excavation is required to indicate what to expect with the process.

- Excavation – With the excavation, the ground needs digging to around 175mm below the paving level. It is imperative that the ground is free from any debris or any problem areas. This is usually done using a mini digger, and the waste is removed via skip or grab lorry.

- Membrane – The membrane’s main purpose is to prevent movement in the stone sub-base, which could affect the surface and stability of the tarmac. A geotextile membrane is laid after excavation and before the sub-base. Though they can be costly, they are essential—expect to pay around £38 per m² including installation.

- Drainage – Ideally, drainage connects to an existing system such as a soakaway, directing water away from the property or public areas. Proper drainage is often a legal requirement to prevent surface water runoff. If not available, a new soakaway with proper piping will need to be installed.

- Stone Sub-base – A 100mm layer of Type 1 MOT or crushed stone is laid and levelled to match the driveway’s contours, then compacted using machinery or tools to form a solid, even base. This step is essential as it supports the weight of vehicles and prevents future movement or cracking.

- Lowering the Kerb – For this step, you will need to have been in touch with the local authority to lower a kerb if needed.

- Edging – The first part of the edging is for structure: the tarmac needs to have this in place to stop it from cracking and from any movement. Edging should be placed approximately 75mm beneath the base using a sand and cement bond, although this can vary slightly depending on the type of edging being used.

- First Layering – Sometimes referred to as the binding course, a rough aggregate is laid down of about 50mm and spread out using a rake.

- Second Layering – Laid shortly after the binder course and spread using a rake or toothless lute for a smooth finish, this is the final section and is much finer. Heavy machinery gives the best results, but a plate compactor can also be used to complete the surface.

- Finishing Touches – In the event any areas require patching or touching up, this will be carried out once the job is almost finished. At this stage the tradesmen will clear the area, disposing of any excess waste and cleaning the area where necessary. Once completed, the driveway should be left to dry.

How Long Should You Leave a Driveway After Tarmacing?

Hot-mix tarmac can typically be walked on and can handle light vehicles after 24 to 48 hours, depending on weather conditions and the specific mix used.

The surface is usually then suitable for normal use after about 7 days, while full curing and maximum hardness can take up to 6 weeks. As such it is good practice to leave an appropriate length of time before using.

One way to help the tarmac cool quicker is to spray the surface with a light mist, although be careful as overwatering can potentially damage the surface.

As for cold lay tarmac, this takes longer to cure and is generally less durable than hot-mix tarmac, so needs to be left for longer.

Do most driveway installers provide a free guarantee?

This is my view. Other traders may vary. Always check and have it in writing just to be sure."

Is tarmac the driveway surface most vulnerable to heavy rain and frost?

Can I Tarmac a Driveway Myself?

Tarmacing a drive should usually be left to the professionals and not taken on as a DIY project.

While even a basic overlay isn't too complicated, the equipment required for the job is specific, and even if competent with this, you would need to hire each item and ideally have someone assist you with the job.

As tarmac is initially a hot liquid that gradually cools once laid, the temperatures will get incredibly hot and hazardous to health if in contact with the skin. Protective clothing is required as a precaution.

When mixing tarmac, the temperatures can get high. As a result, this can be hazardous to your health if you don't know what you're doing and is practically impossible without the right tools.

Making repairs to an existing driveway is much more practical. Cold lay tarmac is readily available from all good DIY stockists, usually in bags of 25kg. It's not unrealistic to purchase several of these and complete the work yourself.

But for larger areas?

You'll need hot mix tarmac. With this method, you will need a separate delivery to your home as it is delivered by the tonne and can be very expensive for smaller driveways.

While the material itself can be cheaper in larger quantities, you still need a place to store it, the equipment hire and the time to complete the work.

Below are the common tools needed for the job:

- Mini digger for excavation £150 per week.

- Mechanical roller at £100 per week.

- Plate compactor cost about £24 per day.

- Tarmac rake - approximately £20, the same as a lute for the second layering after the binder course.

- Loading shovel - as much as £200 per day (non-tracks).

- Carrying bucket £10 to buy outright.

Taking into account these factors, it probably makes more sense to hire professionals to do the job.

Not only do they have all the tools and equipment, but they also have the experience necessary to get the job done safely, promptly and to a high standard.

Is a tarmacked driveway a bad idea if you live in an area with a flood history?

Benefits of Tarmacing a Driveway

Cost-Effective

When compared to alternative driveway materials, tarmac is often cheaper than its counterparts.

It does require specialist equipment to complete the job, but for a simple setup, you could be looking at a couple of days to finish a smaller driveway.

Dries Quickly, Easy to Install

A typical installation can be as fast as 1 to 2 days

One of the benefits of tarmac is it can adhere to many surfaces. It is initially laid as a liquid and then compacted into shape with a roller.

Under the right weather conditions the drying process is swift, and you can walk on the driveway after around 24 to 48 hours, although it is recommended to leave for 7 days until you start parking your car on top of the surface.

Weather-resistant

As a weather-resistant material, tarmac repels water very well, better known and impermeable, and is one of the better options for cold conditions as well.

The only issue this may raise is with drainage, so you will need to ensure that any water doesn't pass onto public spaces; otherwise, you may require planning permission.

Durable and Long-lasting

Unlike concrete, tarmac doesn't crack as much. However, it still requires maintenance in the event of oil spillages - as these can cause cracking.

As a result, it is highly durable and long-lasting and can sustain a heavy flow of traffic. Considering the usage a driveway gets, tarmac almost certainly will have a long life and will only need the occasional repair here and there.

Tarmac Driveway Maintenance Costs

It is recommended to review your tarmac driveway every 5 years, committing to any repair work, such as resurfacing, as and when required. Resurfacing isn't the same as getting the job done again and is simply a new layer that is applied.

Furthermore, good tarmac paint/sealant can be used to prevent any future wear and tear or mishaps with engine oil and fluid. A good sealant can cost within the region of £3 per litre, where 5 litres will provide 6m² coverage.

Tarmac Driveway Repair Costs

A tarmac driveway can be highly resistant to the elements, but there will be occasions when repair work is necessary. Such work would include potholes.

Small repairs can be made to tarmac as it’s relatively cheap to complete and can be done with cold lay tarmac, available to purchase by the bag, you'll need around 25kg for 0.2 m² coverage.

Any sign of oil and grease should be taken care of relatively early as this can wear away the tarmac surface, causing it to crack. Removal can be completed with a simple cleaner. Expect to pay around £10 for a 1-litre bottle of driveway cleaner, designed to remove oil.

Larger cracks and potholes can be repaired by yourself, again with cold lay tarmac, but this is only considered to be a temporary fix and professionals would encourage you to apply hot mix tarmac.

The temperatures are entirely different, and a hotter substance is most likely to bond to the existing surface. If you have small blemishes and cracks, then these can be fixed by cold lay tarmac, costing as much as £7 to £15 for a single bag.

Cost of Resurfacing a Driveway

Resurfacing is significantly cheaper than starting again and having the ground excavated. On average, this will cost £55 per m² - but this can increase or decrease based on the size of the driveway and the location.

One thing to bear in mind is that you can only resurface so many times.

The reason being is it adds around 30mm to your driveway each time applied. Over time, this will rise so that it is within the damp-proof membrane of your home and could, in turn, cause rising dampness.

As an example, two resurfacing should be enough in a driveway’s lifetime, and even if it shows signs of being suitable for a resurface, it’s worth excavating and starting again to ensure the height doesn’t increase too much.

Is it possible to resurface a concrete driveway?

Cold Lay Tarmac vs Hot Mix Tarmac

Cold lay tarmac is much more accessible to non-tradespeople as you can purchase from a local DIY store. Available in bags of 25kg, these typically offer a minimal amount of coverage (around 0.3m²) and are best suited for repairs.

Hot-mix tarmac is cheaper the more you purchase but requires special deliveries and additional equipment.

Cold Lay Tarmac

Pros

- ✔ Easily purchased and you can pack in a normal-sized car.

- ✔ Prices can be competitive if you buy more of it.

- ✔ Saves on labour costs as can be completed by a DIY enthusiast.

Cons

- ✖ More expensive for a smaller job.

- ✖ On average, you'll need within the region of 125kg just to cover 1m². This may require more than one trip in an average-sized car.

- ✖ It's a temporary solution.

- ✖ Does not adhere to the surface as well as a hot mix tarmac due to the temperature.

Hot Mix Tarmac

Pros

- ✔ Compared to cold lay tarmac, it's much cheaper as 1 tonne will provide 8m² coverage, costing on average £45 for said tonne.

- ✔ Offers better coverage and a more permanent option.

Cons

- ✖ The added expense of delivery as sold by the tonne, it cannot be collected in a domestic vehicle - £100 to £150.

- ✖ The mixture is kept heated in transit, so it ideally needs to be applied the moment it arrives.

- ✖ Requires ample storage space and will need to be laid on a tarpaulin in the meantime.

Concrete vs Tarmac Driveways

Generally speaking, tarmac driveways are more cost-effective than concrete driveways.

One of the first things that comes to mind is the durability. Tarmac handles the rain and snowy conditions very well, unlike concrete, which also has the habit of cracking. However, the average lifespan of tarmac is 20 years, whereas concrete is double that and also does not require any sealants and minimal maintenance.

Furthermore, tarmac is a much swifter installation job as work can be carried out on various surfaces with minimal preparation work and can harden in 8 to 10 hours. Tarmac is unlike concrete, which requires a lot more preparation, excavation and time for the concrete to cure - typically a couple of days.

There are differences in price too. While the average price for tarmac can be between £45 and £65 per m², concrete weighs in at £85 per m² on average.

Tarmac Driveways

Pros

- ✔ Easy installation.

- ✔ Can be poured over to a variety of substances (excluding lawns).

- ✔ Excellent in the wet and snow.

- ✔ Cheaper.

- ✔ Can be resurfaced rather than paying out for a new driveway.

Cons

- ✖ Tarmac requires sealants every 5 years for maximum durability.

- ✖ 20-year lifespan (if looked after).

- ✖ Can get excessively hot in the summer.

Concrete Driveways

Pros

- ✔ Concrete doesn't require sealant.

- ✔ Lasts for 40 years if well maintained.

Cons

- ✖ Much more expensive.

- ✖ Needs additional preparation before pouring.

- ✖ Prone to cracking.

Cleaning and Maintaining a Tarmac Driveway

There are a variety of elements that can wear on the surface of your driveway that can simply be cleaned to make it more durable over time and offer a more appealing appearance.

There are driveway cleaning services available and to clean a driveway and seal it costs around £10 per m², so a 40m² driveway would cost £400 for a job that should take around 6 hours.

Of course, you can do the cleaning and maintenance yourself. This process will significantly save on labour costs but will take much longer, and you will need different products for each job.

- Oil patches and grease - Gunk driveway cleaner, or similar, at 2L for £10 on average removed engine spills with ease.

- Algae and moss - standard driveway cleaners cost around £10 for 2.5l, covering 85m².

- Weedkiller - a typical household spray only costs £1.50 and works within 24 hours.

- Push sweeper - instead of hiring equipment, a dedicated machine can cost within £130 and clean faster than conventional brushes. Pressure washers, though fast, can damage the tarmac.

Tarmac Driveway Alternatives

Tarmac is the most cost-effective driveway solution with various benefits that have already been covered. Still, there are alternatives, each with its perks, and the material you use in your next project shouldn't be limited to just one or two options.

What are the most modern types of driveway material in terms of both style/design?

Gravel Driveway

Gravel is the cheapest method and can sometimes look like the most attractive option in some areas.

The price is around the £25 per m² mark for an overlay and double that for when digging is required. One of the issues with gravel is it is continually being moved, and it involves a lot of maintenance. Additionally, it can become very dusty. However, gravel doesn't sink or crack and can easily be topped up.

Block Paving Driveway

Block paving has a high aesthetic appeal as the designs available are limitless, and if there are any areas of damage, individual blocks can be removed and replaced.

This is a timely option. You are paying not only for the cost of materials but also for the skills of the paver. Additionally, a foundation of sand is required for the blocks to rest on, and a sealant is required. Expect to pay around £47 per m².

Resin Driveway

Resin is similar to gravel, only the material is much more compact and less likely to move; the top layer features a resin film.

Due to its permeable qualities, it's efficient for sloping driveways. The average cost for resin will be around £40 per m². but can increase significantly depending on the materials used, and a higher-end price is more in the region of £70 per m².

Concrete Driveway

Concrete driveways come in at £85 per m², so one of the costly options, concrete does have a lifespan of 40 years if well looked after.

Unlike tarmac, it doesn't require sealant, but it is prone to cracking and not so good in poor weather conditions.

Cost of Removing a Tarmac Driveway

Perhaps you need to update or replace your existing driveway, have had to undertake works on drainage, and, as a result, will have to have your driveway removed.

Tarmac is an easier material to work with. It's mostly labour-intensive and doesn't necessarily need skilled workers to complete. It is something you could do yourself as you don't need specialist equipment, but it will take a good deal of time and, among many things, will need to skip hire and removal. For a 4 to 5-yard skip, you could be looking at around £110 to £240, which would be sufficient for an average-sized driveway.

If you employ professionals to do this for you, it's a lot less hassle and could only take a day or two to complete. Expect to pay the same day rate as it would cost for a driveway installed.

In short, this will take about 1 to 2 days of work for labourers and would cost between £300 to £800 (including skip hire and removal).

Checklist: Hiring a Tarmac Driveway Installer

Tarmacing requires attention to detail to ensure the driveway has suitable drainage solutions and that the tarmac is laid on good-quality groundings. It's recommended to get at least 3 quotes before committing, which is achievable with the help of MyJobQuote without any obligation to go ahead any further.

- Have you requested more than one quote? Multiple written quotes let you compare prices and services better. Also, make sure the company inspects the driveway in person rather than quoting over the phone—you might save a lot if resurfacing is enough instead of full excavation.

- Have you checked customer reviews and testimonials? Checking feedback shows the company’s reliability and quality. If possible, view a current or previously completed job in person, a driveway may look fine initially but show poor workmanship over time.

- What experience does the company have? Knowing their experience helps ensure they understand key issues like proper drainage, essential to avoid long-term driveway problems.

- Do you know what’s included in the tarmac driveway quote? Clarifying this avoids surprises. For example, whether work is done by hand or machinery affects quality and project length.

- How many workers will be on the job? Knowing this helps manage timing and cost expectations. Also ask if extra charges apply when more workers are added due to delays or other issues.

FAQs

When was tarmac invented?

Is modern tarmac made with tar?

What is tarmac made of?

What is the best time of year to tarmac a driveway?

How long should a tarmac driveway last?

What is the most common material used for a driveway?

How often should I apply a sealant to the tarmac surface?

Sources

https://www.planningportal.co.uk/permission/common-projects/paving-your-front-garden/planning-permission

https://cheltenhamsurfacing.co.uk/news/the-advantages-of-tarmac-why-it-outshines-other-surfacing-options/

https://www.bituchem.com/knowledge-hub/road-surfacing-whats-the-difference-between-tarmac-bitumen-and-asphalt/

https://www.uksurfacings.com/news/steps-to-tarmacing-a-driveway/

https://www.tarmaseal.co.uk/product/tarmac-restorer-red/

https://www.bestcosurfacing.co.uk

https://sealmaster.net/

https://www.pavingexpert.com/tarmac02